Laser Ultrasonics

Process highlights

Laser Ultrasonics is a non-contact technique which is based on the use of lasers for the generation and the detection of ultrasonic waves. It is a valuable process which allows a better knowledge of materials by, for instance, characterizing their microstructure, detecting bulk flaws or identifying phase transformations through the fabrication process.

While the traditional way has been to use mechanical transducers generating a vibration at the surface of the parts to be diagnosed, laser ultrasonics rely on a different mechanism: a nanosecond laser is focused on the part, which induces either a thermal or a plasma expansion if the fluence is over the ablation regime. Such a phenomenon then causes the appearance of different kinds of ultrasonic waves (>20kHz) like shear (transverse), longitudinal or surface waves.

The detection is also based on the use of a laser source that is operates in continuous or pulsed regimes, with a longer pulse width than the generation laser for the latter case. This source is coupled to an interferometer. The aim of the pair is to measure beam displacements occurring at the part surface by detecting instantaneous optical frequency changes.

What we offer

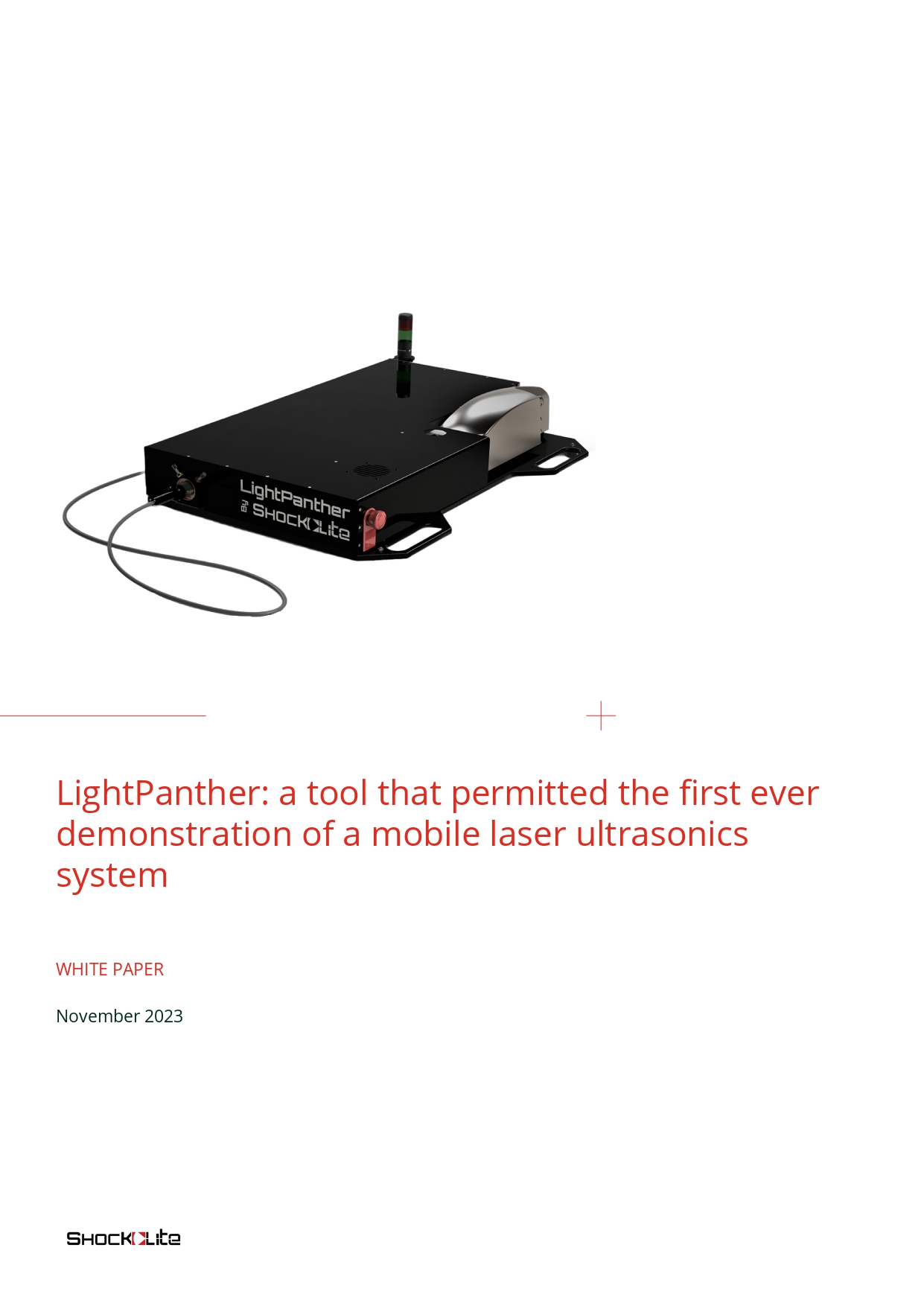

The LightPanther system is a powerful tool for the generation of ultrasonic waves as it can be integrated in a Laser Ultrasonics setup. In fact, if the detection side (laser and interferometer) are also fibered, it can give way to an all-fibered Laser Ultrasonics system which can perfectly fit industrial operation.

ShockLite has also the capacity to design and manufacture various optical modules such as optical heads that combine the generation and detection beams but also scanning heads.